Why Register?

- List Your Business

- Business Matchmaking

- WhatsApp Chat

- Personal Messaging

- Showcase Your Products

Product Pictures

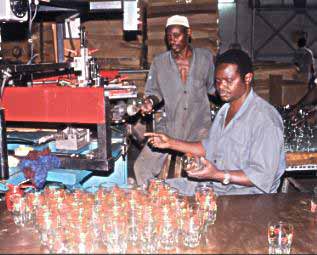

The plant's production capacity has increased from 120 - 180 tones of glass per day. Inside the plant, temperatures of about 1400 degrees, fluorspar, sand and other chemicals are mixed and melted into liquid before they are made into attractive finished products. Situated on 2.75 acres of land in Ganjoni and Liwatoni road, the Glass plant is currently providing direct employment to over 426 workers. Majority of the workers at the plant are locals - this is in line with the company benefiting locals of the area where they operate. In the quest of turning around the plant, expensive and newly mechanized machines were imported.

The new equipments included pressing and printing machines that were installed at the plant. Employers have the back up of fully computerised equipments imported from Germany, France and Italy. Glass packaging has several benefits to the Cosmetic, Food, Glass tableware, Pharmaceutical and Soft drink industries.

The plant has established its market base to far flung areas in and outside the East African region. Products from Milly Glass Works are exported with in and outside East African regions to Zimbabwe, Djibouti, Eritrea, Indian Ocean Islands and West Africa. Coca Cola Company is one of our largest clients.

The firm supplies the Soft drink making company with various shapes of bottles. Simple and popular glassware for homes and production of pharmaceutical products for storing syrups and tablets is also done at the Milly Glass Works. Food industry where production of jars for storing jams, ketchups, squash and mustard as well as product bottles for soft drink are all manufactured at the Milly Glass Works. The management feels that it is high time Kenyans are encouraged to buy what they can make by so doing the will give greater impetus to the slogan 'Build Kenya, Buy Kenya'.