Why Register?

- List Your Business

- Business Matchmaking

- WhatsApp Chat

- Personal Messaging

- Showcase Your Products

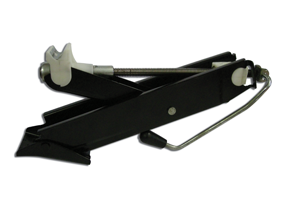

Product Pictures

Ramsay Engineering (Pty) Ltd. manufactures metal, plastic, and leatherette automotive components and metal stampings for automotive industry in South Africa and internationally. Its activities include metal stamping and forming, plastic injection moulding, automotive trim, component assembly, product development, and total industrial engineering. The company also provides metal forming and fabrication tools, jigs, injection moulds, and special purpose machinery. It serves construction, agricultural, security, and other industries. The company was founded in 1953 and is based in Pietermaritzburg, South Africa.

Ramsay Engineering (Pty) Ltd is privately owned, volume manufacturer of metal , plastic and leatherette automotive components. Our core competence is Metal Stamping which contributes to 60% of our sales revenue.

Our other divisions at Ramsay Engineering include Plastic Injection Moulding, Automotive Trim, Component Assemblies, Automotive Accessories, Logistics, Quality, Tool and Die, Product Development, Total Industrial Engineering and Training.

This variety of manufacturing processes allows for the supply of a broad range of automotive components. Our company readily accepts challenges and actively applies innovation and expertise to solving a multitude of customer problems. A dynamic approach together with strong ethics enables the Ramsay Engineering to live by the motto: “Our customers come first.”

Ramsay Engineering (Pty) Ltd is a volume manufacturer of automotive components in metals, plastics and leatherette, ranging in weight from a few grams up to several kilograms. Preferred projects are where the minimum volumes are 50 000 units per annum.

Ramsay is a privately owned company established in 1971, with our head office in Pietermaritzburg, KwaZulu-Natal and an assembly plant in Rosslyn, Gauteng, South Africa. Today there are 500 employees and our facilities occupy 26 000 m² .

Our core competence is Metal Stamping which contributes 60 percent of our sales revenue. Our other divisions include Plastics, Automotive Trim, Component Assemblies, Accessories, Logistics, Quality, Tool and Die, Product Development, Total Industrial Engineering and Training.

This variety of manufacturing processes allows the supply of a broad range of automotive components. Our customers benefit from our diverse capability as it allows them to deal with one supplier for a part comprising different materials and related processes. Manufacturing divisions are managed by qualified production specialists and back-up is provided by experts who facilitate the smooth running of all manufacturing equipment. We are able to supply a comprehensive package, from the design through to the delivery of the final product.

The company is committed to the use of cutting edge technology and has recently installed new levels of technology in the Metal Pressing and Tool and Die manufacturing facilities. Ongoing investment in technology and equipment serves to improve the output of products and services from Ramsay Engineering.

All activities are conducted in strict accordance with the international requirements of ISO/TS 16949.The principles of total quality management are applied throughout the company with all quality problems being analysed to determine the root causes and resolved using PDCA cycles. Our company is ISO14001 compliant and is fully committed to reducing all forms of wastage and the recycling of materials wherever practical.

Reduction in energy usage and minimisation of our carbon footprint of the overall manufacturing facility is part of the ongoing operation of the Environmental Management Policy. Safety is also a priority across our company and all requirements of the South African Occupational Health and Safety Act are adhered to.

Our Final Goods facility feeds our customers’ assembly lines 24 hours a day on a JIT and Kanban basis, thus ensuring line side continuity at the various vehicle assembly plants.