Why Register?

- List Your Business

- Business Matchmaking

- WhatsApp Chat

- Personal Messaging

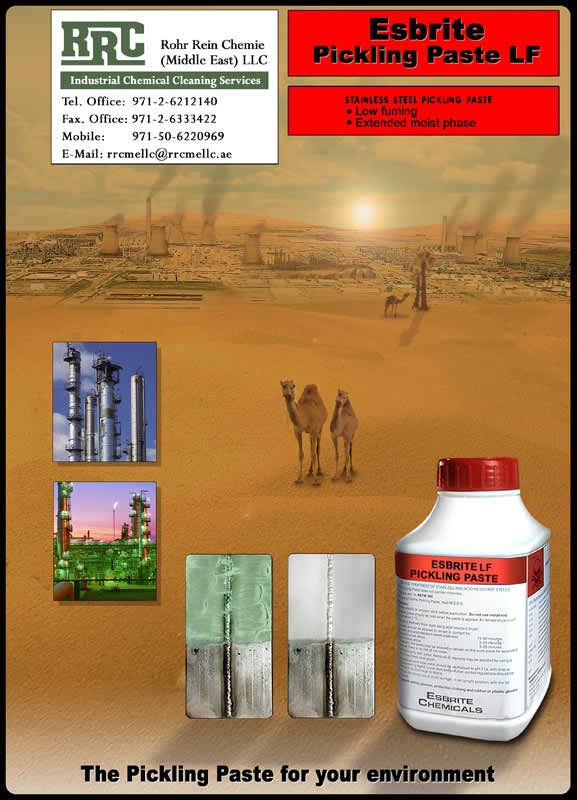

- Showcase Your Products

Product Pictures

The company supplies a comprehensive pickling and passivation service to stainless-steel fabricators from its service facility in Sebenza, Edenvale, on the East Rand. The factory, which covers 700 m2 , has a large receiving and dispatch area, which allows for prompt offloading, dispatching and reduced turnaround time. This allows for optimum use of transport, which is critical during times of high fuel and transportation costs.

The large area holds a comprehensive range of various sizes of dip-tanks for austenitic and ferritic treatments. It also gives the company enough space for spray applications of larger fabrications, which cannot be processed through the dip-tanks. "Dipping is our preferred option as it gives a brighter and more consistent finish to processed items when compared to other means of treatment," explains Gordon. Ultimate finishing in the form of electropolishing items is also carried out. He also points out that his company carries out an on-site pickling and passivation service using its own specialised application and safety equipment and boasts that the company's prompt service gives an efficient turnaround time which facilitates the logistical planning of the client.

"We are conscious of health and environmental considerations and have a fully-operational effluent facility where all effluents are treated and disposed of according to municipal requirements. Any metallic by-products are disposed of through recognised waste-removal authorities. About future plans, Gordon says he would like to see more capital investments in the South African stainless-steel industry in order for the market to expand and create more jobs for local people.